How to Predict Profile Front Scrap with a Novel Analytical Equation

Abstract

Have only a die print and you need to estimate the front scrap? Here you can find a new analytical equation!

Editor's Note: Die-Related Extrusion Defects is an ongoing series dealing with the analysis of the defects encountered in extruded profiles that are related with the die design and its behavior under load. It will describe the physical origin of those defects, including those related to poor mechanical properties and provides design practices to minimize them.

At the end of each process stroke the back end of the old billet material that completely fills the die starts to interact with the front side of the new billet loaded into the press. This back end material is usually contaminated by oxides, dust, or lubricant, thus producing a transition zone that extends to a variable length. In the case of structural applications, it becomes clear that the length of the profile marked by the charge welds (called "front scrap") must be cut off and scrapped. Therefore, an accurate prediction of this portion of the profile becomes mandatory.

Several contributions to research and literature have proved that finite element analysis (FEA) is the most reliable approach to scrap prediction.

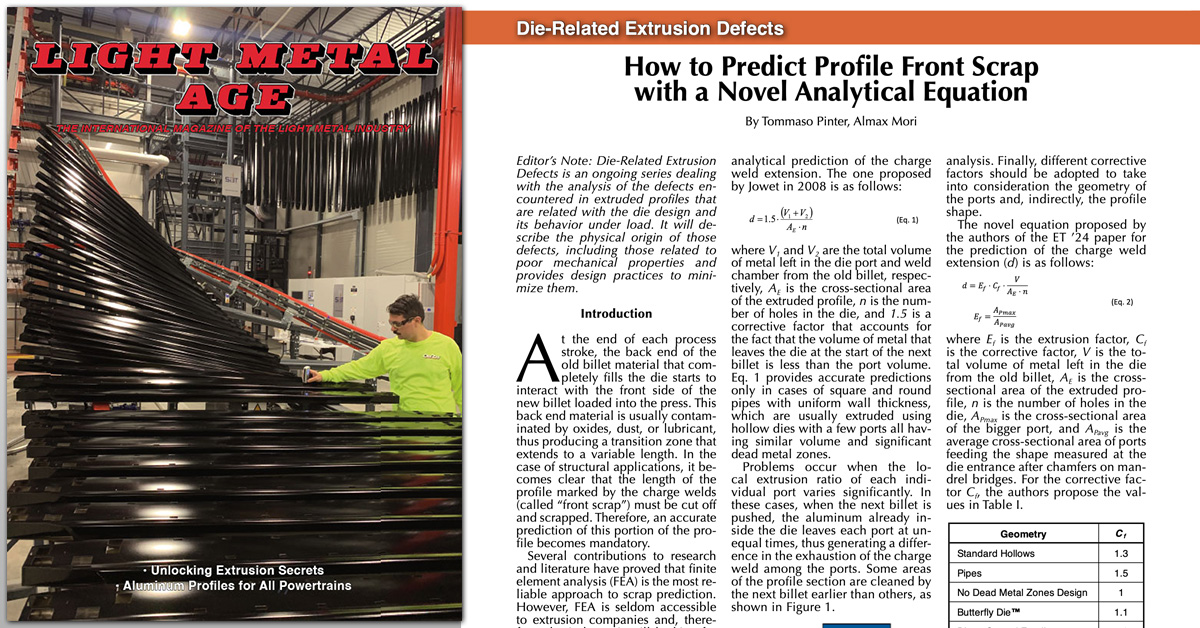

However, FEA is seldom accessible to extrusion companies and, there-fore, the industry is still looking for a valid alternative. This article discloses a new user-friendly equation for scrap prediction in direct aluminum extrusion that appeared in the proceedings of the ET '24 extrusion technology conference.