How to Predict and Counteract Wall Thickness Contraction in Hollow Sections

Abstract

Editor’s Note: Die-Related Extrusion Defects is an ongoing series dealing with the analysis of the defects encountered in extruded profiles that are related with die design and its behavior under load. It will describe the physical origin of those defects including the ones related with poor mechanical properties and provides design practices to minimize them.

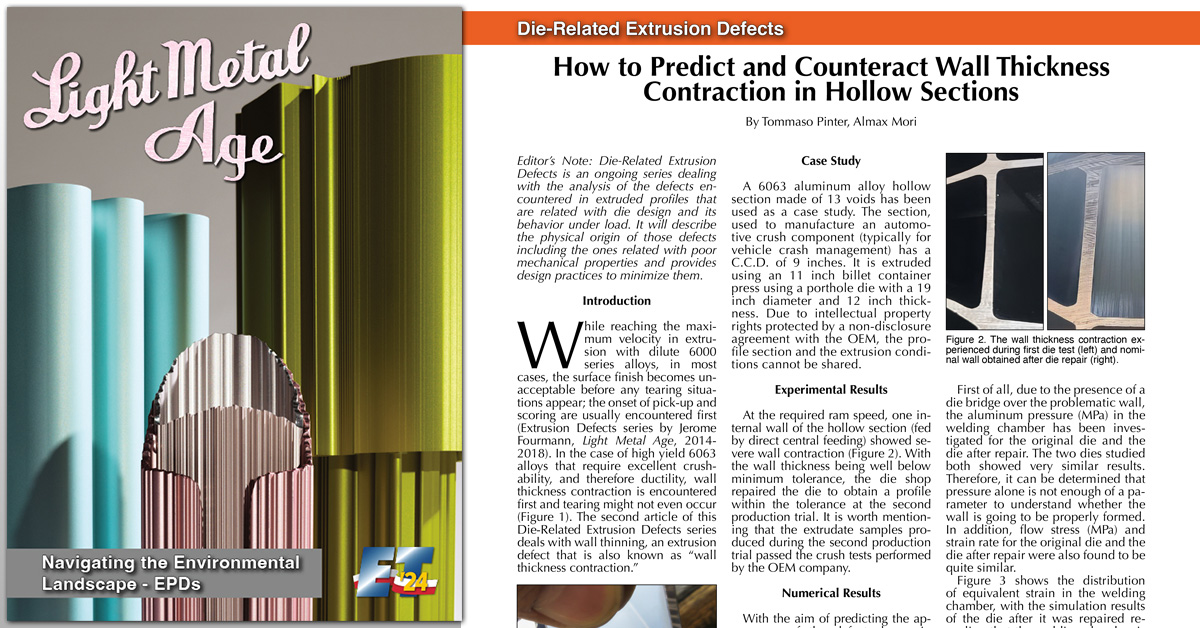

While reaching the maximum velocity in extrusion with dilute 6000 series alloys, in most cases, the surface finish becomes unacceptable before any tearing situations appear; the onset of pick-up and scoring are usually encountered first (Extrusion Defects series by Jerome Fourmann, Light Metal Age, 2014-2018). In the case of high yield 6063 alloys that require excellent crushability, and therefore ductility, wall thickness contraction is encountered first and tearing might not even occur (Figure 1). The second article of this Die-Related Extrusion Defects series deals with wall thinning, an extrusion defect that is also known as “wall thickness contraction.”